On a March 27 conference call with Stifel Capital Markets and transportation executives nationwide, Steve summarized the results of the annual Princeton Consultants survey about tech disruption in freight transportation and logistics. This Freightwaves article summarized the survey and the findings. In the second half of the call (lightly edited excerpts below), Steve explained that in the Coronavirus environment, executives may benefit from optimization techniques to mitigate supply chain failures such as the “bullwhip effect.”

The elephant in the room is the Coronavirus disruption of supply chains. I think many supply chain and logistics professionals are asking, how did our supply chains fail so massively, and whose fault is it?

Jay Forrester, a brilliant professor at the MIT Sloan School of Management, in 1960 created the “Beer Distribution Game,” also known as the “Beer Game.” To this day it is played by business school students, undergraduates, even high schoolers. It is a favorite at executive retreats. Tens of thousands of people have played The Beer Game (described here), which shows ambitious, competitive people how hard it is to manage supply chains.

The consistent finding is that everyone plays terribly. According to a current MIT professor of systems dynamics, CEOs of logistics companies and their executive teams are no better at the Beer Game than high school students.

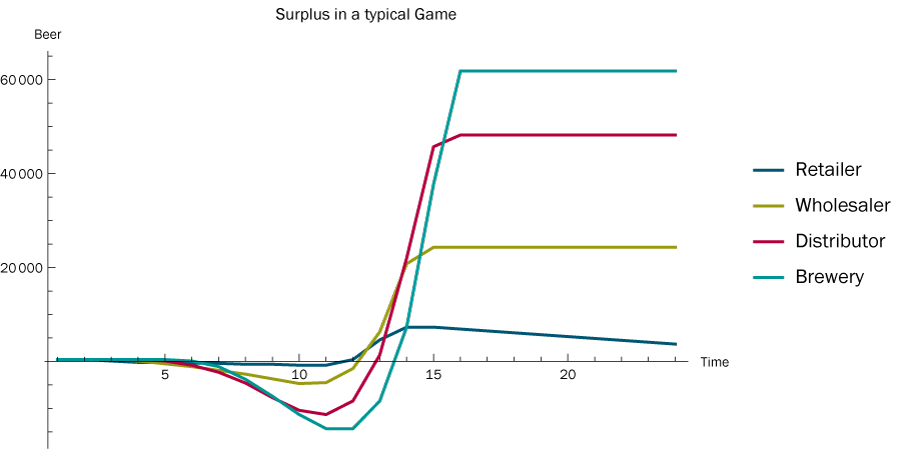

The game’s typical result was initially called the Forrester effect, but we now call it the bullwhip effect. On the left side of the graph below, as time goes on, things are fine.

The way the game is designed, around the second or third week, demand spikes up a little bit. Shortages occur; the line is dipping down. People start ordering and ordering and ordering, and then in all these supply chain simulations there is a massive overordering, and you see the bullwhip effect. Ultimately, there is a flood of oversupply. Everyone loses. The question is, who loses the least? There is no trick to the game. If there were, people wouldn’t have been playing it for 50 years.

In this game, beer can be replaced with any commodity: face masks, hand sanitizer, swabs, toilet paper. The bad news is that as realistic as the Beer Game is, real-world logistics is a lot more complicated. For example, the rules of the Beer Game haven't changed since 1960. In our world, the rules of the game are in constant flux. There are black swan events like the Coronavirus. Everyday there are many news stories about shortages; there are bullwhips all around us.

There is good news. In the real world, we can jump around the limitations of the Beer Game. Its key limitation is that you can’t communicate or coordinate except by placing orders. That one seemingly innocuous little rule—that all you can do is place orders and not collude—creates these bullwhips. The answer is to improve communication. All parties in the supply chain can communicate. Many disruptive technologies in freight transportation—Blockchain, the Internet of Things, 5G, Uberization—are designed to improve communication and visibility.

In the Beer Game, the customer demand is completely unknown. In the real world we can use and improve our forecasting technology. One thing I want to say: the idea that we can take machine learning and put it on inventory levels and get better forecasting—that is only half-true. It is not true if you are using it to look at historical data and infer what next week is going to look like; other technologies like simulation optimization—must be brought into play as well.

The Beer Game dictates a transportation length and it has a certain level of delay. In our world, in a crisis like we are in, resiliency suddenly makes a lot of difference. Every transportation mode right now seems in crisis. Drones and self‑driving vehicles add diversity to our important transportation network, just like different types of investments in a portfolio do. Diversity equals resiliency.

The Beer Game relies 100 percent on human players who are subject to rules of thumb, bias and panics. In the world that we are trying to make more resilient, we can use smart systems conventionally called “AI” right now. As I mentioned earlier, these systems must include not just machine learning, but also simulation-optimization. Lastly, in the Beer Game, the cost is fixed, while in reality, we can improve things with automation.

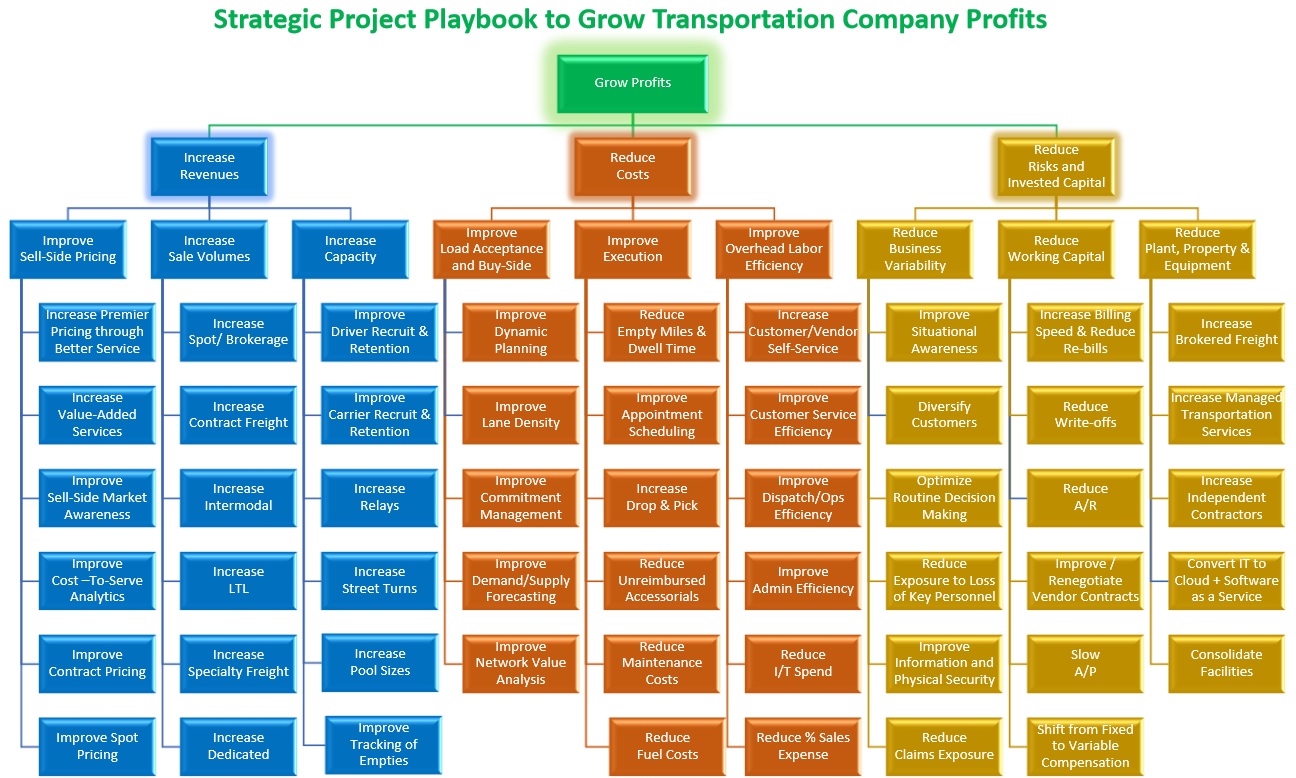

Let me finish with “what you can do.” On this slide, here are plays in the playbook that we have seen over the years.

Pick one and let’s talk about it, let's think about the main levers in your organization. With each company, there are different supply chain circumstances where certain plays make sense today. Are there ways to increase revenues, reduce cost, or reduce risk in invested capital? In a time when we are all struggling with great uncertainty, and some of us are struggling really with finances, the areas at the far right are suddenly more important. In good times, most executives are just thinking “increase revenues, reduce cost.” As soon as things get very uncertain, many are looking to reduce risk.

I wrote a book, "The Optimization Edge," that explains optimization as taking types of assets and automating the decision process behind them. The goal is to get multiple outcomes. You don’t have to trade off efficiency for nimbleness. You can have a system that is very efficient and makes you nimbler in hard times. When you hire a lot of personnel, some are experienced, some are less experienced, some have their eye on the ball, and some can drift. In contrast, optimization is very consistent and very transparent about how it works. Optimization is also very fast—that’s why it is nimble.

The Beer Game hasn't changed in 50 years but our real-world version has, and our job is to keep adapting, especially in extraordinarily challenging times.

To talk with Steve or request a copy of his presentation for Stifel, email us.