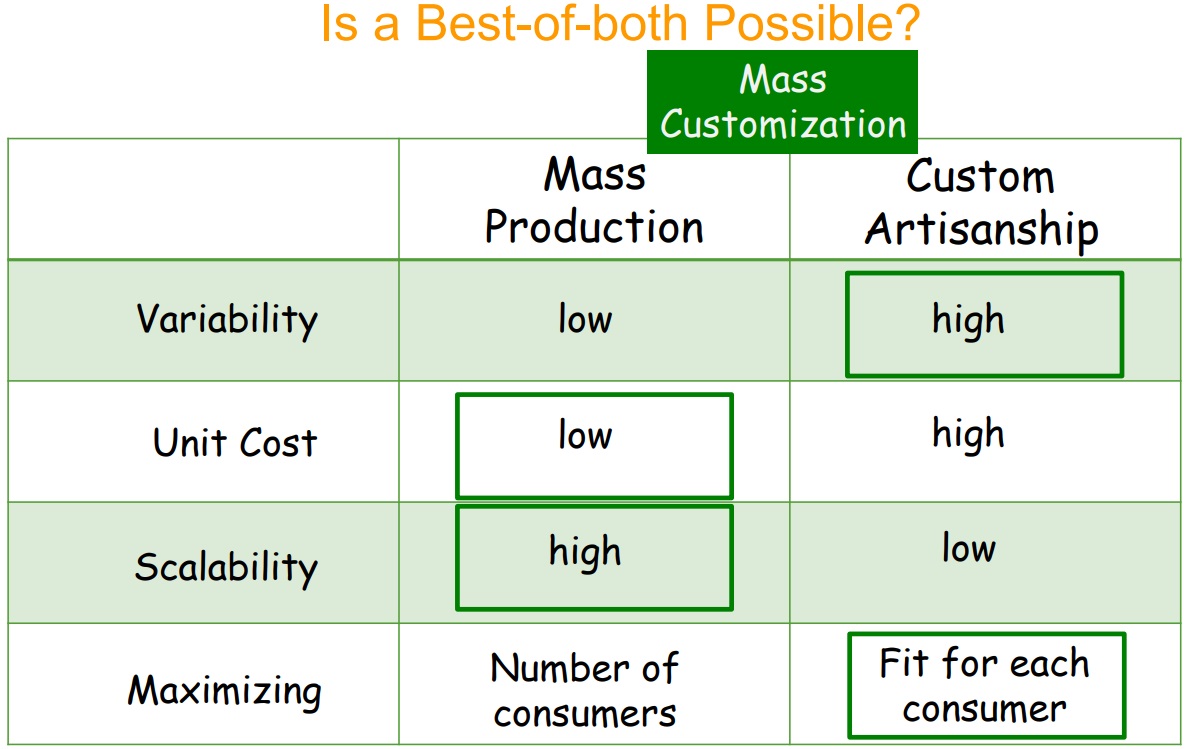

In manufacturing, there is often a competition between mass production and custom artisanship: produce vast quantities of product at low cost or produce it in tiny amounts at high fit. Can you achieve low unit cost and scalability from mass production, and the high necessary fit for each consumer from custom artisanship?

Yes, it is possible through “mass customization,” as evidenced at a frontier of healthcare manufacturing. In precision medicine, there is variability, which is valuable because it helps meet individual needs and get the best fit for each consumer. There are different therapies for each patient because we all have different genetics, different health at any given time, different allergies or sensitivities, different medications we are taking, and so on.

Successful Mass Customization as Seen in CAR-T Therapy

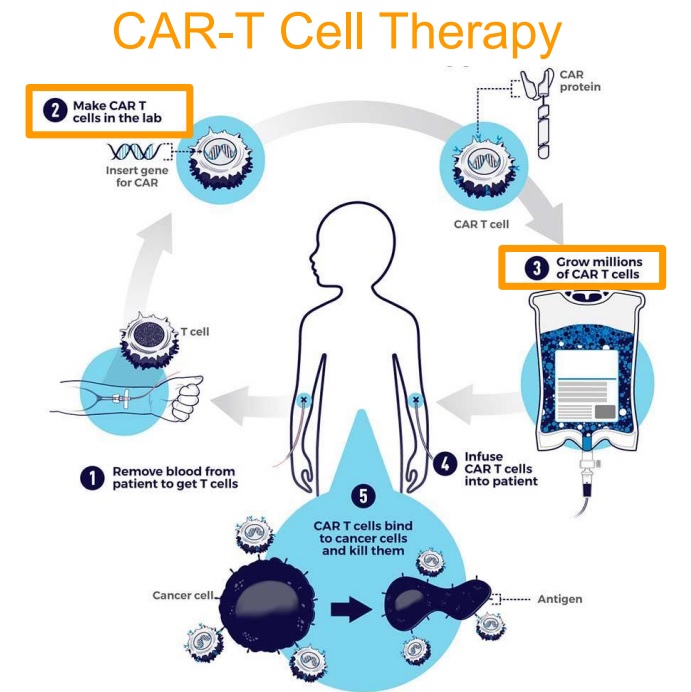

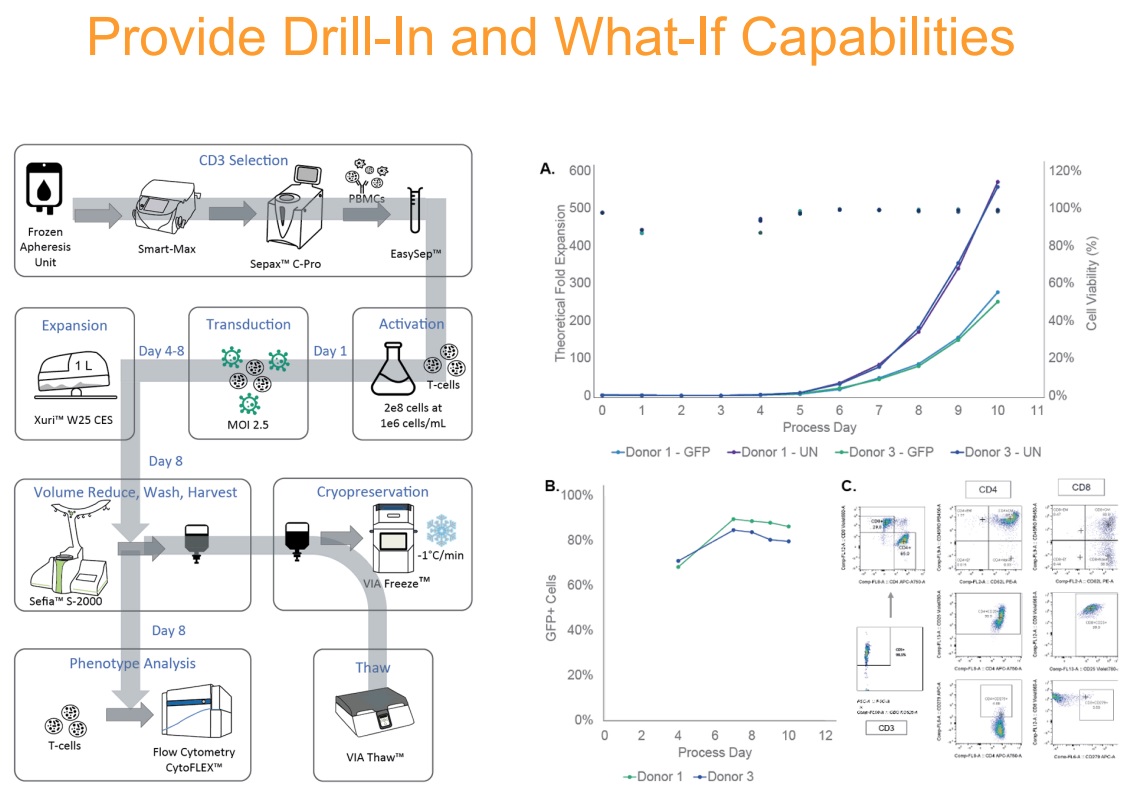

Let’s dive deeper into precision medicine, examining a project we conducted with a biotech firm that was developing a revolutionary cancer therapy, CAR-T, which I will summarize in general terms. In CAR-T an individual’s T cells are obtained and then shipped to a manufacturing facility that bioengineers the T cells to fight cancer. A therapeutic amount of bioengineered cells is grown and then sent and infused into the patient. Crucially, the new cells are not rejected by the patient’s immune system because they were grown from the individual’s native T cells.

There are two main steps in CAR-T manufacturing: producing cells in the lab and growing them in a sufficient quantity.

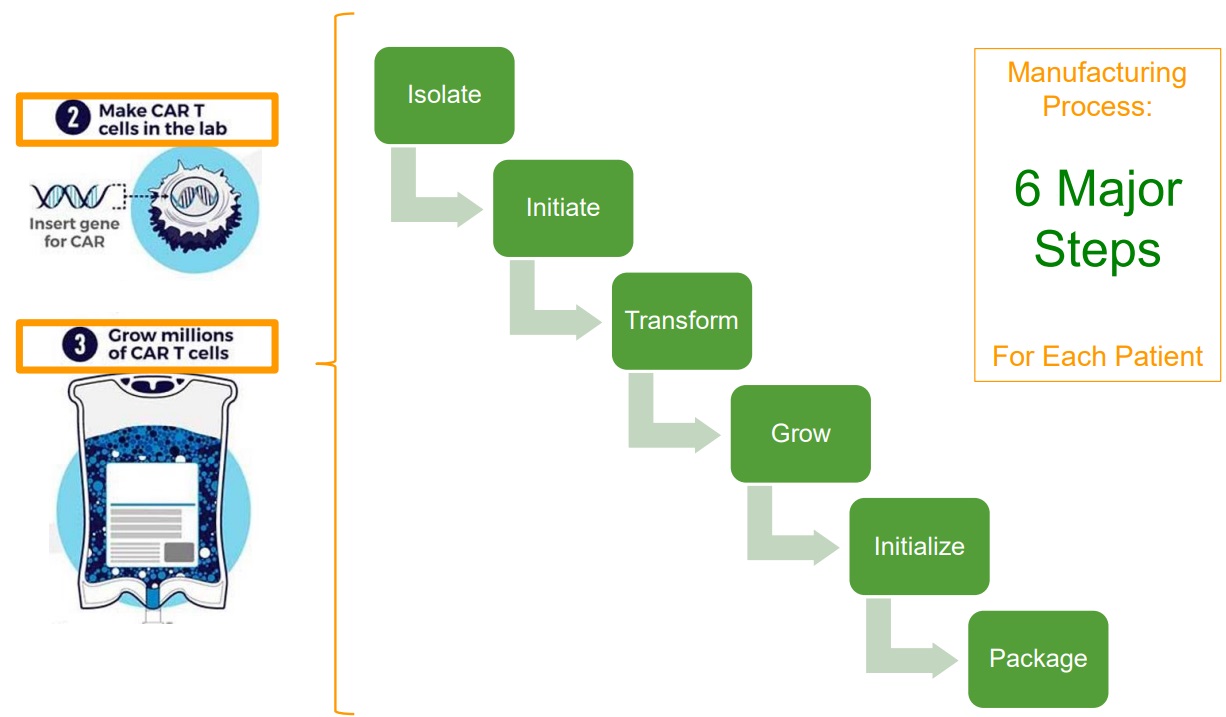

In our project, we learned that the “two steps” actually break out into six steps, and each is necessary for each patient.

Because this was frontier work, there was freedom to design each step any number of ways. Processes could be highly manual, performed individually in batches of varying sizes. There were different combinations of labor: it was possible to have a specially‑trained person at each step, or to have more general‑purpose higher paid employees who were more flexible and able to flip between steps. Similarly, there were many types of equipment that can grow cells and perform the necessary steps. Lastly, the facilities could be set up very differently: clean rooms and other rooms could vary in number and size.

From so many possibilities, how could executives evaluate and choose the best labor and process, equipment, and facility? Precision medicine was not enough; mass customization was required. The executives sought to demonstrate that the therapy worked, and then understand how to create the appropriate manufacturing facility to produce at scale.

Overcoming Challenges

There was a lack of data and set of industry best practices, because these were brand‑new processes. The staff were very expensive and required costly training, and flipping workers across modes was difficult and time‑consuming. The process needed to be cost-effective and scalable very quickly once FDA approval of the therapy was achieved.

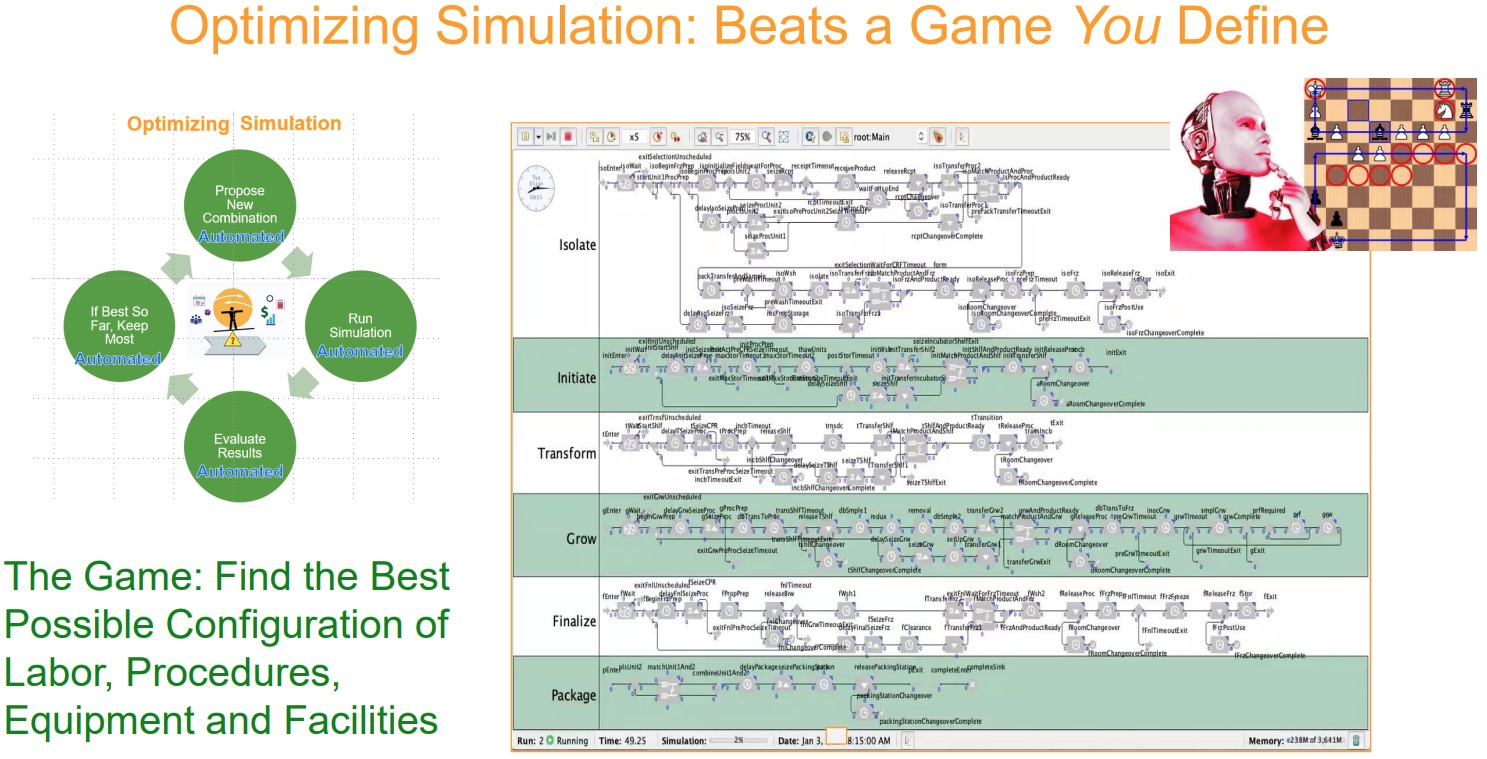

The traditional approach to solving configuration problems is simulation: to rigorously model processes, labor, machines, and facilities. Simulation is best used, however, with a specific set of focused choices. In this case, everything was in play and there were trillions of combinations. It would be too expensive and time‑consuming to build typical simulation models.

In typical workflows, the simulation run is automated, and the evaluation of results, deciding what is best in a run, and then proposing what to change in the next run, is done manually. Our team sought to automate those manual processes and improve on them.

Solution: Optimizing Simulation

We employed optimizing simulation, which can automatically evaluate trillions of combinations and pick the best set. Providing learning at machine speeds, it is the technique used famously by AlphaGo Zero to “beat” chess.

Optimizing simulation works in highly multi‑dimensional problems: in this case, the winning strategy chooses the best combination of labor, procedures, equipment, facilities, and they all interrelate. The type of equipment may indicate the types of labor needed. The more automation, the less skilled labor, for example. If there are multiple labor classes, there may be fewer clean rooms needed.

After the optimal strategy is identified, the model has to be translated back into communication pieces that nontechnical stakeholders can evaluate. It is necessary to show them the drill-down of the statistics for each step. In this pharmaceutical, precision medicine example—and in many manufacturing environments—there are very few true generalists. There are many deep specialists who must be walked through the model’s recommendations, and they need to be shown numerically why something is better.

Takeaways

By using optimizing simulation, we helped a startup innovator create a new process, using mass customization for precision medicine in CAR‑T therapy. The company was subsequently acquired for $9 billion.

There are many opportunities to explore mass customization. More and more manufacturers are innovating by producing small batch sizes cost‑effectively, establishing new ways of conducting business by integrating AI-powered technologies in the movement called Industry 4.0.

To my mind, mass customization exemplifies the Lean culture because it combines low unit cost with individualized fit at scale. In transforming processes from mass production to mass customization, new sets of job tasks and jobs are created. We must upskill our workforce for this new era.

The new manufacturing frontier is not going to thrive on benchmarking because there are no prior practices to benchmark against. Optimizing simulation can overcome a lack of data by finding new possibilities and pursuing new paths—and help invent new factories.

Based on our firm’s decades of experience with optimization and related technologies that are related to AI, we advise executives to avoid banking on a “moonshot.” Optimizing simulation supports “Agile AI” in which the team progresses from a small and testable step to a slightly bigger and usable step, and so on. Agile AI can help build support in manufacturing processes or in manufacturing design.

In short, this is an era of technical disruption. In our view, leadership must not settle for incremental improvements to the status quo. Innovations are emerging everywhere; optimizing simulation and mass customization should be considered wherever possible.

To discuss this subject with Steve, email us to set up a call.